Your margin for error shrinks long before a serious safety, quality or human performance failure.

We help you see where it’s happening—early.

A 4-week, AI-powered Capacity Assessment for 24/7, safety-critical operations that uses your existing workforce data to pinpoint where fatigue, overtime, staffing gaps, and experience levels are eroding margin and driving elevated risk for serious failures.

Most safety critical organizations are excellent at the WHY and have invested heavily in:

The Problem

WHY vs. HOW Gap

Understanding energy sources and risk exposure

Engineering controls and Barriers

Rigorous investigations and corrective actions

These explain WHY incidents occurred - and the mechanism behind failure

The HOW explains the path to failure.

Before controls fail or incidents occur, everyday normal work conditions begin stacking the odds of failure and eroding your margin to fail safely:

Fatigue from planned & unplanned OT and extended runs

Staffing gaps and unplanned coverage

Skill and experience imbalances

Production pressures and tradeoffs

These conditions are rarely visible - until something goes wrong.

Incidents are rare.

Conditions in normal work are constant.

What We Do

AI-Powered Capacity Assessment

Our Capacity Assessment is a short, fixed-scope diagnostic that complements your existing processes by making human and organizational conditions visible before an incident.

Using existing workforce management data, we uncover:

Where fatigue, overtime, and workload accumulated

How experience gaps aligned with critical work

When operations were running with little margin

Patterns that recur across incidents, near misses, and “good days”

This shifts learning from what failed to how failure became possible.

Reveal the HOW behind safety, quality and performance outcomes.

How our Capacity Assessment Works

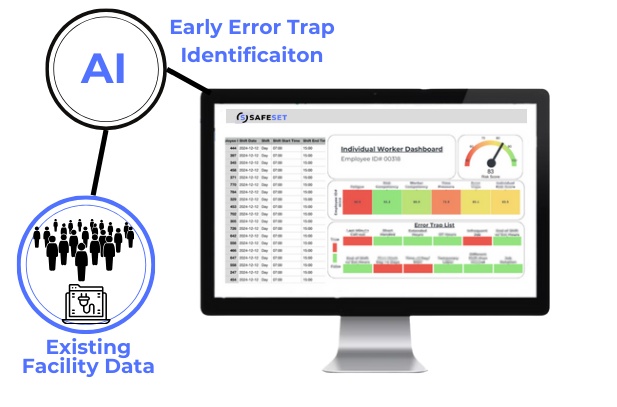

Step 1: Utilize existing Workforce Management Data

Step 2: Run data through our proprietary AI Pattern Recognition Engine

Step 3: Uncover low capacity areas when your operation was running on luck

1.

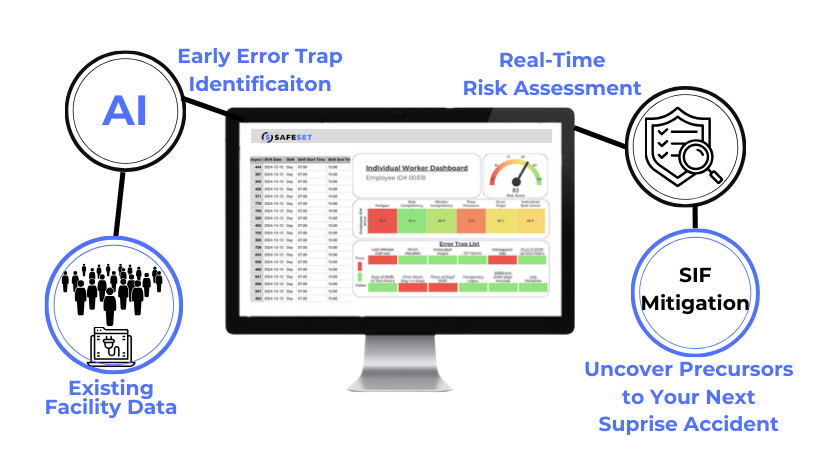

Real-Time Operational Intelligence at the Front-line using Existing Facility Data

Seamlessly & securely integrate with your plant's existing data streams to capture operational intelligence in real-time from “Normal Work” variability. No additional hardware needed.

2.

AI-Driven Pattern Recognition for Early Error Trap Detection

Leveraging advanced algorithms, it identifies emerging patterns and subtle anomalies in real- time to signal potential issues early on.

3.

Real-Time Monitoring & Risk Assessments

By continuously comparing live data with expected performance benchmarks, our system provides ongoing risk assessments highlighting deviations from normal operations.

4.

From your visualization command center, you can gain visibility into critical hot spots from error producing conditions before your people interface with risk

Heat Map Visualization for Critical Hot Spot Detection

You already know WHY incidents cause harm and the mechanics behind it.

We reveal HOW the path to operational failures happen.

No new systems. No wearables. No personal data.

-

An error trap is a condition or situation in the work environment that increases the likelihood of human error. These traps don't cause harm directly but set people up to fail by making mistakes more probable, often without them realizing it. Recognizing and managing error traps is key to building resilient systems that anticipate human fallibility.

-

Hazards are direct sources of potential harm. They are the energy that can cause injury, damage or loss and are inherently dangerous. Error Traps on the other hand, are conditions that increase the likelihood of human error. They don’t directly cause harm, but they set people up to make errors.

-

Error traps are often missed in traditional risk assessments because those assessments are typically hazard focused and not context-focused. Those “conditions for failure” are the contextual factors—the error traps—that only show up when you look closely at how work is actually done, not just how it was designed.

-

Some error traps can only be uncovered with non-traditional safety data because traditional safety metrics—like incident rates, audits, and compliance checks—tend to focus on outcomes and rule-following, not the conditions that make errors more likely. These conventional tools often miss the subtle, day-to-day realities of normal work where error traps actually live.

FAQs

Pricing

90 Day Money Back Guarantee

Worry free access to cutting edge technology and Human & Organization Performance tools to accelerate your resilience journey

Bring Transparency to the normal work conditions that challenge the way your people work successfully

Contact Us for Pricing

Data Integration

Detection of Hidden Error Traps

Real-time Monitoring

Actionable HOP Insights

Operational Intelligence Directly from the Front-line

AI-Powered Solution